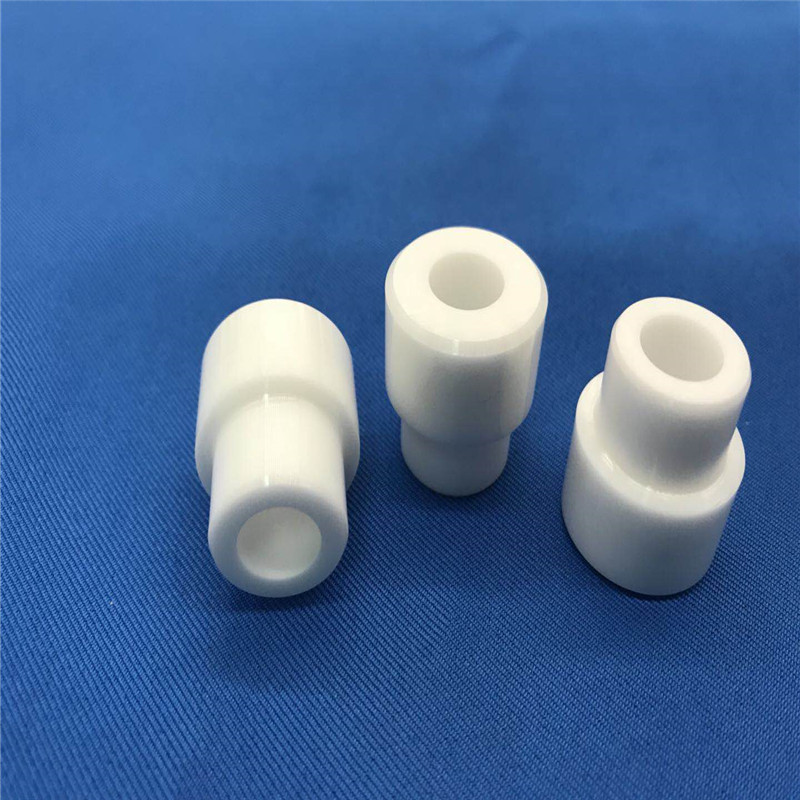

High Precision Insulating Zirconia Ceramic Guide Bushing

Basic Info

Model No.: MRT-340

Product Description

Product Description:

High Precision Insulating Zirconia Ceramic Guide Bushing

We manufacture & supply advanced technical ceramic tubes custom machined to your specific design. Ceramic tubes are finding their way into more and more application due to their highly desirable mechanical, thermal, and electrical properties. Ceramic tubes can be used in extreme environments unlike many other materials. Precision Ceramics has a wide assortment of tube sizes available; depending upon the material, we can machine tubes with incredibly tight tolerances. Additionally, Precision Ceramics has standard size Alumina Tubes available in a variety of sizes and purities. Other materials may be available in custom dimensions and specifications. We are happy to offer material design & application assistance for any special requirements.

| Product Name | High Precision Insulating Zirconia Ceramic Guide Bushing |

| Material | alumina |

| Color | White, Black , Blue , Yellow |

| OD | 0.2mm - 200mm, And According to drawings |

| Length | 5mm - 400mm, And According to drawings |

| Surface Roughness | Ra0.05 |

| Torlerance | +/- 0.001mm |

| Lead time: | 15 days |

| Max. working temperature | 1500 -2200 °C |

| Samples | Avaliable |

| Shipping: | Air Express (DHL/UPS/TNT/ FedEx) or Ocean Shipping |

Properties Sheet:

The products are made of high purity zirconia ceramic and alumina ceramic material, which have

advanced and excellent performances, fabulously popular .

| Properties | Units | 95 Alumina | 99 Alumina | ZrO2 |

| Density | g / cm³ | 3.65 | 3.9 | 5.95-6.05 |

| Water absorption | % | 0 | 0 | 0 |

| Coefficient of thermal expansion | 10-6/K | 7.9 | 8.5 | 10.5 |

| Modulus of Elasticity Young's Mod | GPa | 280 | 340 | 210 |

| Poisson's ratio | / | 0.21 | 0.23 | 0.3 |

| HV Hardness | MPa | 1400 | 1700 | 1300-1365 |

| Flexural Strength @ room temperature | MPa | 280 | 320 | 950 |

| Flexural Strength @700°C | MPa | 220 | 230 | 210 |

| Compressive Strength @ room temperature | MPa | 2000 | 2200 | 2000 |

| Fracture Toughness | MPa *m 1/2 | 3.8 | 4.3 | 10 |

| Heat conductivity @ room temperature | W/ m*k | 18-25 | 26-30 | 2-2.2 |

| Electrical Resistivity @ room temperature | Ω*mm2 /m | 10^15 | 10^16 | 10^15 |

| Max use temperature | °C | 1850 | 2200 | 1500 |

| Resistance to acid alkaline | / | high | high | high |

| Dielectric Constant | / | 9.5 | 9.8 | 26 |

| Dielectric Strength | KV/mm | 10 | 10 | 10 |

| Thermol Shock Resistance | △ T ( °C ) | 220 | 190 | 280-350 |

| Tensile Strength @ 25 °C | MPa | 200 | 248 | 260 |

| Thermal Conductivity(25℃) | W/m·K | 30 | 35 | 3 |

Detailed Images:

Advantages of Al2o3 ceramic piston plunger pumps:

1. Refractory.

2. Self Lubricating.

3. Long Service Life.

4. Good Polished Surface.

5. Environmental and Healthy.

6. Superior Mechanical Strength.

7. High Corrosion and Wear Resistance.

8. Good Insulation Performance Precision.

9. High Temperature and Pressure Resistance.

10. High Purity Zirconia and Alumina Ceramic Material.

- High hardness, long service life, not easy to break and wear resistance.

- Non-conductive, anti-static, ceramic material itself with the insulation of electricity and magnetism properties.

- Corrosion resistance, high temperature resistance, can be applied to a specific environment, such as acid and alkali resistance.

1. Refractory.

2. Self Lubricating.

4. Good Polished Surface.

6. Superior Mechanical Strength.

7. High Corrosion and Wear Resistance.

8. Good Insulation Performance Precision.

9. High Temperature and Pressure Resistance.

10. High Purity Zirconia and Alumina Ceramic Material.

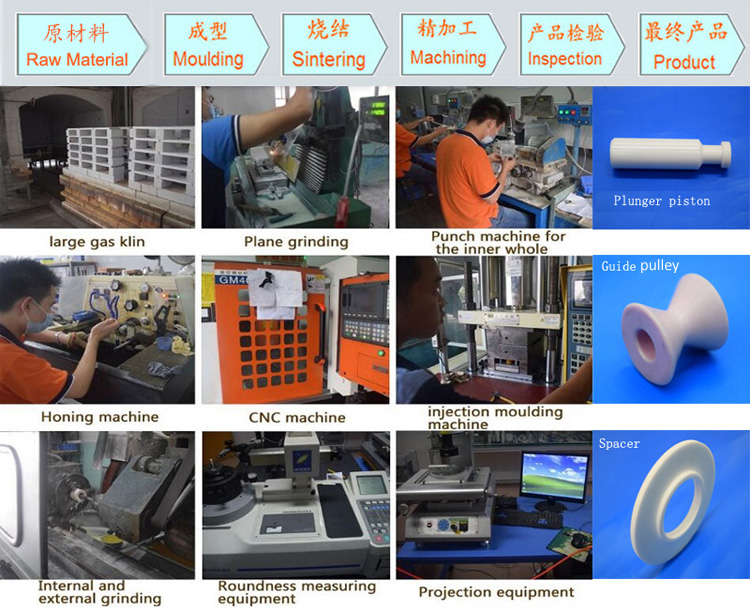

Production process:

One-stop production, from the raw material (powder) to final products, control the quality strickly of every production link.

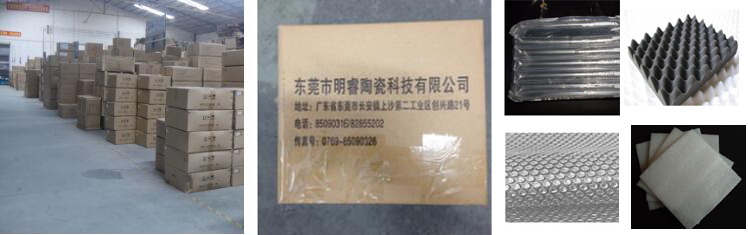

Packaging and Shipping:

General piston plunger pumps will be packed in a bubble bag individually, then separated by a foam,

finally put in standard export carton packing, or OEM packing.

Shipped by Express ( DHL, TNT, UPS, Fedex, EMS ), Air, or Sea transportation.

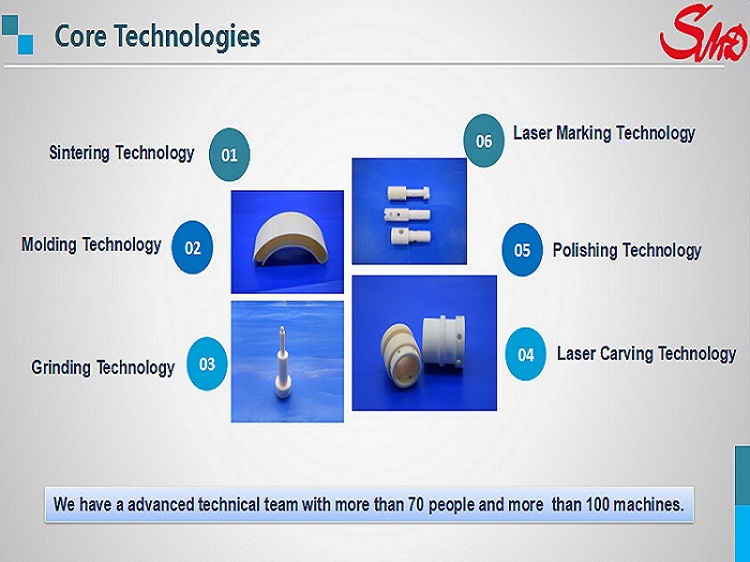

Mingrui has professional OEM experience in manufacturing industrial ceramic parts for so many years. And

very advanced technologies in the production of Zirconia Ceramic Rod and Alumina Ceramic Rod, Zirconia

Ceramic Ring and Alumina Ceramic Ring, Zirconia Ceramic Tube and Alumina Ceramic Tube, Ceramic Pin,

Ceramic shaft, Ceramic Plate and Block, Ceramic Sleeve, Ceramic Injector Nozzle, Ceramic Dispensing

Valve, Ceramic Injection Pump, Ceramic Plunger Pump, Ceramic Piston, Ceramic Stick, Ceramic Washer,

and Semiconductor Industry Ceramics, Machinable Ceramic Part, Ceramic Electronics Accessories, etc..

They are applicable to Electrical, Appliance, Mining, Oil & Gas, Energy & Power, Food & Medical, Agriculture, Aerospace,

even other high-end fields.

We can make the product according to your drawings, custom the size, color and thickness etc..

Our products with some certificates, such as SGS, CE, TUV, etc..

Workshop overview:

We have almost all the precision processing machines of ceramic products.

Product Categories : Ceramic Ring > Alumina Ceramic Ring