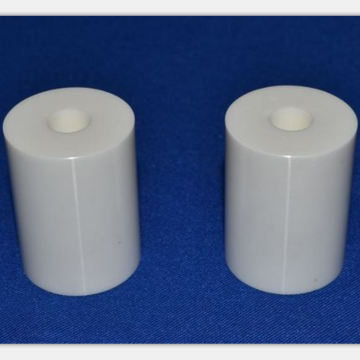

High Hardness Mirror Polished Ceramic Zirconia Tubes

Basic Info

Model No.: Customized

Product Description

High Hardness Mirror Polished Ceramic Zirconia Tubes

These zirconia tubes are made from ytrria partial stabilised zirconium oxide (YSZ) material, the most highlighted strength is the toughness and flexural which is far cry higher than other kinds of advanced ceramics. It's perfectly overcome the inherent britleless and friability of ceramics itself. Therefore, the working life of zirconia tubes is significantly extended. For example, the value of YSZ zirconia ceramic toughness is over 6.5~8 MPam^1/2 that is 1.7~2 times than alumina ceramics. When both zirconia ceramic tubes and alumina ones fall from same height in the air, you will find the zirconia tubes have a much more complete appearance without chippings, breakage.

In addition, working under extremely high temperature is another remarkable chacteristic of zirconia tube, it can be up to 2400℃ well. The melting point even reach 2700℃. What's more, ceramic zirconia tubes own other features as following table

| High density | ≧ 6g/cc |

| High compressive strength | ≧2000MPa |

| Excellent wear resistance | 10 times higher than 95% alumina ceramic and metal |

| Better chemical stability | 5 times better than alumina ceramics for corrosion resistance |

| Low thermal conductivity | 1/10 of that of alumina ceramic |

| Low thermal expansion coefficient | The value is around 8.0~9.5 1×10^(-6)/℃ |

| High dielectric constant | The parameter is around 29 (E) under 1MHz |

In most applications, more fine surface would be beneifit to funcations, the service lifespan, fitting relationship with other matched parts. That's why these zirconia tubes need to be machined, polished after sintering. We could achieve these secondary manufacturing processings well at our facility with our comprehesive equipment.

The applications of zirconia tubes

Zirconia tubes have very widespread applications, mainly including pumps, valves, compressors, fluid flow control systems, printing press parts, high-temperature furnace and so on.

Contact us if you need more details on Mirror Polished Zirconia Tubes. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Zirconia Ceramic Tube、Zirconium Oxide Tube. If these products fail to match your need, please contact us and we would like to provide relevant information.Product Categories : Ceramic Tubes > Zirconia Ceramic Tube